Common Loopholes in ERP Manufacturing Software

A manufacturing ERP is a type of Enterprise Resource Planning (ERP) software that aids in the planning, managing, and delivering of specific features that support various business operations for a manufacturer.

Numerous day-to-day reports and data accumulation in the form of repositories need to be managed. Therefore, the aim is to have a smooth system that delivers an easy and uniform flow of information under clearly defined codes and procedures.

Testing plays a vital role in ensuring a successful ERP system implementation, with continuous system testing helping spot loopholes and providing quality delivery throughout the business processes.

This article will highlight the importance of resolving loopholes in manufacturing ERP software and ways to maintain error-free operations.

Why do you need ERP Manufacturing Software?

Many small businesses may not require a robust ERP system at the beginning of their operations, but as the size of the organization grows, and more stakeholders come into the picture, implementing an ERP system becomes inevitable.

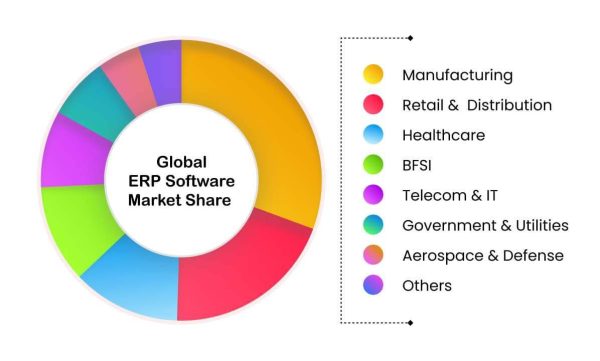

The global market for ERP software has bolstered with both SMEs and established organizations valuing its true potential. By 2025, the size of the global ERP software market is projected to reach $70.3 billion, growing at a market growth rate of 10.5% CAGR. In addition, the report highlights the rising demand for ERP software in the manufacturing industry, claiming a prominent share.

Here are six reasons you should consider using a new ERP manufacturing software:

1. Centralize Data

The ability to manage all your business processes from a single centralized digital platform is one of the significant benefits of an ERP for a manufacturing enterprise. Looking at the size of an enterprise, most manufacturers have subdivided processes that include manufacturing, accounting, shipping, financials, human resources and more.

Businesses manage many functions separately, which are likely exposed to many challenges that include data errors, duplication of functions, miscommunication etc. All these issues can be curbed with an efficient ERP solution in place.

2. Real-time Project Tracking

Real-time inventory tracking is one issue that most manufacturers need help with. A few major consequences of this can be higher expenses, insufficient storage space due to excess inventory, and low productivity due to inadequate inventory.

A solid and well-established ERP system allows managers to have a grip over these functions and monitor the progress of any project in hand, all in one place. Issues like delays in deliveries and urgent product requirements can be addressed immediately, along with reliable analytical reports from real-time data management.

3. Better Budgeting

Cost reduction is one of the most significant critical drivers for adopting a new ERP solution. After successfully implementing an ERP system within your organization, you get updated and real-time records of your operational systems’ functioning, reducing your administrative cost significantly.

4. Improved Productivity

A well-established and integrated ERP system helps your enterprise to eliminate redundant processes that can be easily handled by automated software. Strategies that can take forever to be accomplished otherwise. It covers regular tasks like generating reports, maintaining inventory, employee timesheet tracking, etc., that are simplified daily, ultimately resulting in improved productivity.

5. Better Client Handling

ERP systems allow your sales teams to analyze the shifting interests of your clients more holistically which can help you build better sales strategies for improved lead generation. Furthermore, it allows your teams to keep your clients in the loop with the progress of your project in hand with updated real-time data shared at equal intervals.

6. Better Features

With the ever-changing digital transformations in place, ERP solutions come with the latest technologies and updated software systems customized for the individual needs of your customers – another strong reason for you to opt for and implement an ERP system. Examples include Machine Learning (ML), Artificial Intelligence (AI), Data Analytics (DA), and the Internet of Things (IoT), all integrated to deliver the necessary ease of business required in your organization.

Typical Errors in Manufacturing ERP Software

Now that you know a few of the numerous reasons you require implementing a new ERP system in your business operations, let’s look at some of the most typical ERP implementation pitfalls that every manufacturing company must avoid.

1. Inaccurate Planning

As mentioned a couple of times in the above sections, inaccurate requirements gathering, and no proper planning can result in a total failure of your ERP implementation. Noting that one of the essential ingredients of a successful ERP implementation is automation, the fact that its effectiveness depends majorly on the processes it automates cannot be overlooked. Automation in itself comes with many challenges that need to be addressed. Therefore, automating an outdated and inefficient process makes it run faster and improves your overall efficiency.

2. Ignoring the End-Users from the Decision-Making Process

It is important to note that the significant end-users of your ERP system are not just the C-level executives but the rest of the organization as well. Ignoring taking appropriate input from all these executives can lead to misunderstanding and operational complications. Departments like finance, operations, manufacturing and warehouses need to be looped into an organizational-level change like this to ensure an easy and smooth transition.

A smooth and effective change management system is the key here. Making a list of all employees affected by this change and ensuring proper hands-on training are all essential parts of this system. The change must be managed in three vital organizational areas: people, process and technology. The people factor here requires intensive planning, strategizing and execution to avoid last-minute failures.

3. Inadequate Budgeting

Enterprises often need to pay more attention to the overall cost of planning, strategizing and executing a big move as ERP implementation into their organization. It’s not just the cost of implementation but the after-training and maintenance costs that can take a toll on your overall project budgeting if not calculated comprehensively. The major blunder organizations make by trying to achieve more with fewer or inadequate resources end in total project failures.

4. Go Live in One Go

Many technical experts still believe implementing an ERP system is more like a traditional waterfall model. On the contrary, the need to incorporate a more agile implementation system with modern technological solutions must be understood here. An ERP system is complex, and it may be challenging to determine all the implementation requirements in one go. Moreover, customizing, integrating, and training also takes time and close monitoring. Taking baby steps along with a reliable ERP implementation service provider is the key to this journey.

5. No Maintenance Plan

Implementing an ERP solution is part of the system, and responding to user-escalated issues and fixes is another. A proper maintenance plan that includes a customer success team that occasionally addresses your employees’ problems is necessary to help improve the system to a level that suits every element of your business processes.

Solve ERP Implementation Challenges

Here are a few ways to dodge ERP implementation errors without dropping into the pit of failure.

Properly Define ERP Implementation Objectives

To analyze the before and after effects of implementing ERP, an organization must specify why it wants to do so. Typical ERP implementation goals include things like:

- Streamlining procedures

- Faster cycle times

- Lessening manual labor

- Lowering costs

- Boosting effectiveness

Precise User Participation & Training

Management and staff must participate actively in the training sessions devoted to the ERP manufacturing software. So that they can use ERP software without difficulty after Go Live, a thorough understanding is required.

Post-Implementation Support

Inadequate post-implementation support is one of the biggest bottlenecks. Selecting an ERP vendor willing to offer post-implementation support and necessary service add-ons is the better course of action. In addition, such metrics should be considered to increase the ROI of your ERP manufacturing software.

Ensure Hassle-free ERP Implementation

Many believe implementing ERP software is a once-in-a-lifetime opportunity for any enterprise. But on the other hand, it’s more of a continuous journey towards an updated, integrated, and collaborative functioning of any system. Because change is the only constant, businesses must devote time to strategizing, planning, and executing their move to benefit everyone in the organization.

ImpactQA’s ERP testing solutions provide unique methodologies and a comprehensive approach to enterprise software testing for all business types. We offer tailored solutions for your end-to-end ERP testing projects, from test planning, strategies, and preparation to test management, coordination, and implementation, through our cutting-edge QA services.